-

Description

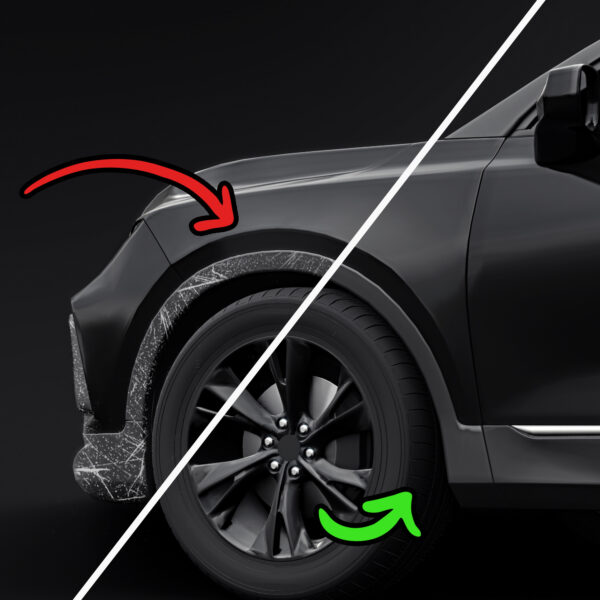

Professional, colourless protective film – protective laminate for lamps, sills, car bodywork and bumpers.

High-quality colourless film (protective laminate) ORAGUARD 270G is a colourless, glossy PVC laminate with a UV filter, 150 microns thick! The laminate provides high protection for areas particularly vulnerable to scratches, sand or stone impacts. Recommended for protecting headlights, mudguards, sills, mirrors, bonnets and lower door panels. It can also be used under door handles, where the car's paintwork is exposed to frequent scratches from fingernails.

-

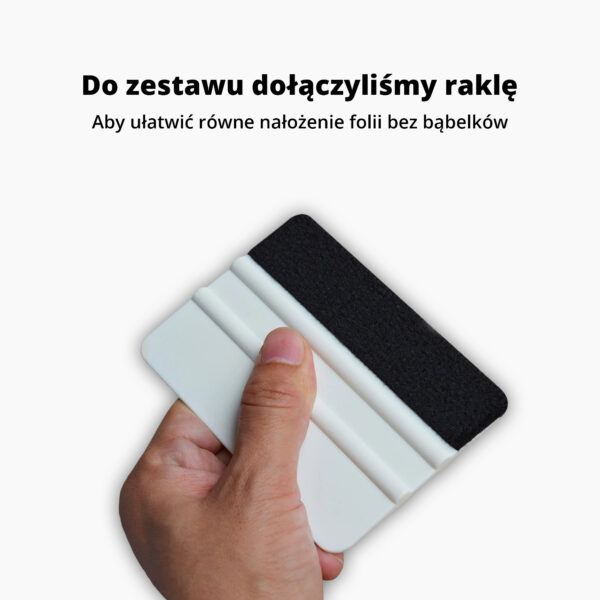

Tools useful for installing film

-

- squeegee – included in the set

- sharp knife for cutting film

- heat gun for imparting slight plasticity to the film

- water for application (preferably demineralised)

- agents for cleaning and degreasing the surface

- paper tape (for preparing the template)

-

-

Installation of film

Remember, the recommended temperature for applying the film is +10°C.

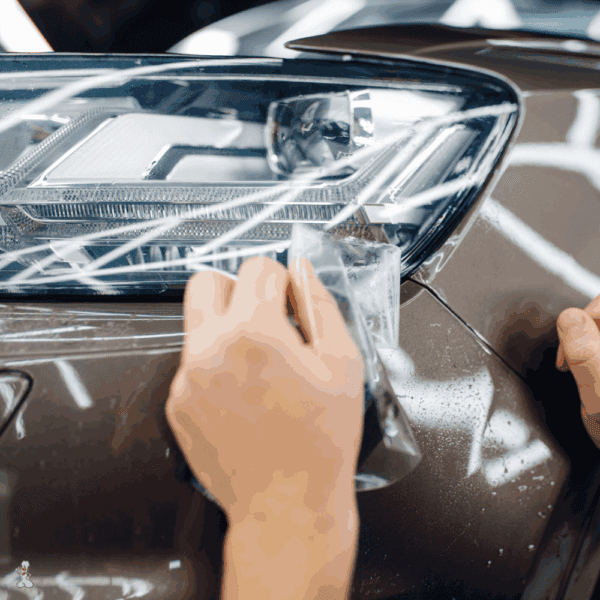

- Thoroughly clean the surface to which you will be applying the film. Remember about recesses and gaps. After cleaning, degrease the entire surface.

- Peel the film off the backing paper and spray the adhesive side with demineralised water. Also spray the element to which the film will be applied with water.

- Apply the film to the element and start smoothing it from the centre towards the edges.

- Ensure greater plasticity of the film by using a heat gun. Under the influence of high temperature, the film becomes slightly plastic and easier to fit to such a curved element.

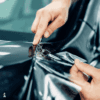

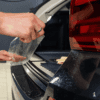

- After sticking the film, it should be trimmed (cut off any excess film). The photo shows an example of our work with a blade on glued film. Cutting film on paintwork or lights requires skill and experience, as there is a high risk of damaging the paintwork. The film should be cut and not sliced.

-

Removing the film

Before removal, the film should be heated with a heat gun, then it will come off the element nicely along with the adhesive.

-

Technical data of the film

- Adhesive: Solvent-based polyacrylate, permanent

- Covering material: Silicone-coated paper, 137 g/m²

- Thickness*: (without protective paper and adhesive layer): 150 microns

- Shape retention (FINAT TM14): when applied to steel max <0.3 mm

- Water resistance (DIN50021): no changes observed after 100 hours at 23°C when applied to aluminium.

- Temperature resistance: when applied to aluminium, -40°C to +110°C, for a short period of time, max. 24 hours, at +100°C, no changes observed.

- Adhesive strength (FINAT-TM I, after 24 hours, stainless steel): 20 N/25 mm

- Resistance to solvents and chemicals: 72 hours at room temperature. When applied to aluminium, the film is resistant to most oils and fats, fuels, aliphatic solvents, weak acids and bases.

- Recommended application temperature: above +10°C.

-

Manufacturer's comments and recommendations

The surface to which the film is applied must be cleaned of dust, grease and other contaminants that could adversely affect the adhesion of the product. Freshly varnished or painted surfaces should be left to dry for at least 3 weeks. The compatibility of selected varnishes or paints with self-adhesive film should be checked before final application of the film. Before applying the film, check that there are no chemical reactions between the film and the substrate. Matt films are more sensitive to processing than glossy films. Therefore, they should be handled with greater care, both during application and cleaning. Contamination affects the appearance of matt films, so these materials should be cleaned more frequently. In addition, all information regarding film application published by Orafol Europe GmbH should be taken into account.

-

Packaging and shipping

We pack stickers rolled up into tubes in sturdy corrugated cardboard boxes.

Reviews

There are no reviews yet.